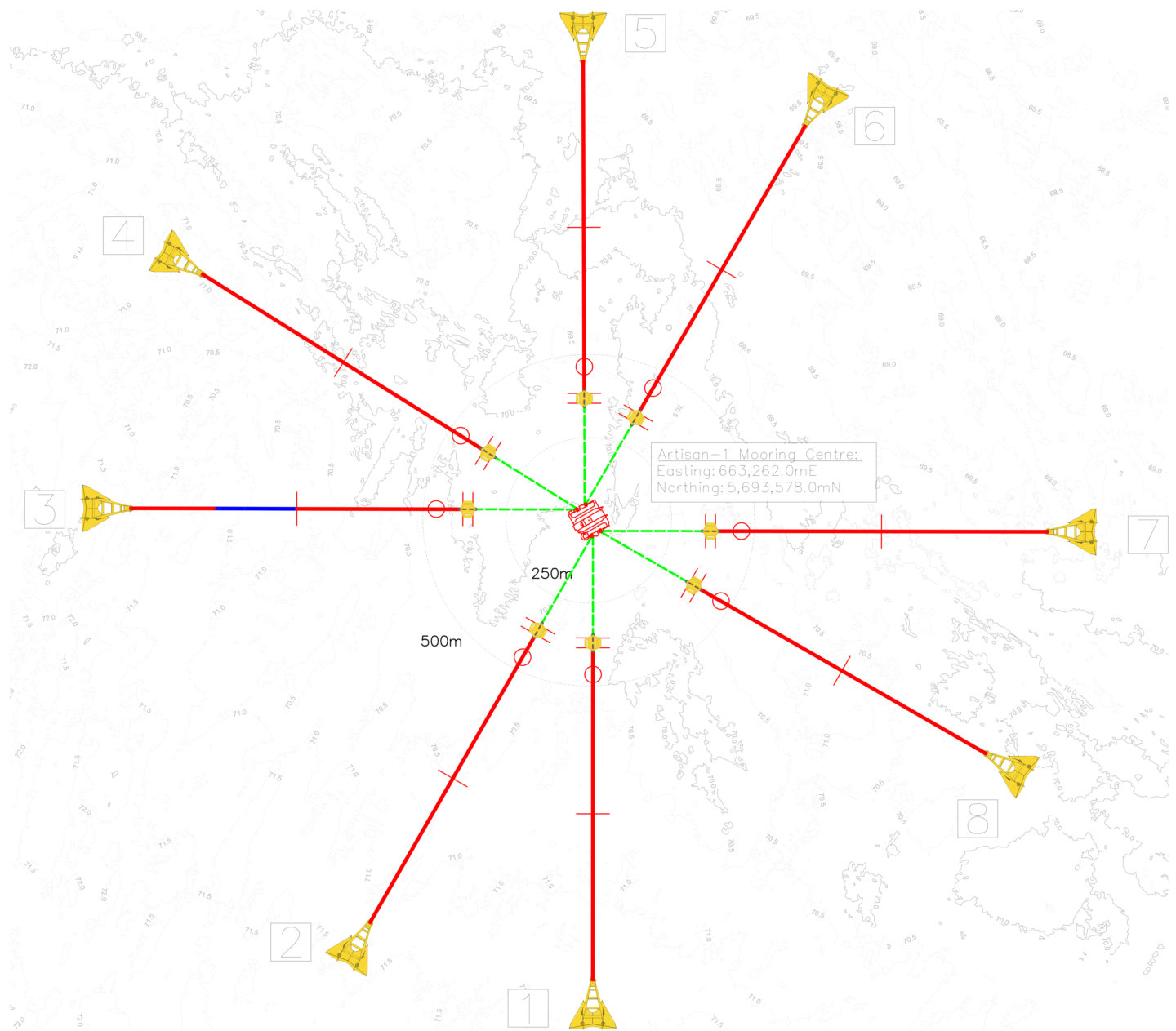

8PT PRELAY MOORINGS, ARTISAN-1, OTWAY BASIN, WESTERN VICTORIA

Deep Sea Mooring was contracted to provide mooring services for Diamond Offshore's Semi-Submersible MODU Ocean Onyx in the Otway Basin in water depths ranging from 70m to 110m. Each location comprised of 8 prelaid mooring lines which were hooked-up upon rig arrival.

In addition to equipment, Deep Sea Mooring provided engineering and marine services, along with personnel (including rig movers, engineers and marine supervisors) to support the operations offshore.

The Rig was towed from Cold Stack in Melbourne to Artisan-1.

This complex project demonstrates how Deep Sea Mooring uses its capabilities to manage the development and execution of a turn key mooring solution. The 8-point mooring system used at the location was driven by very challenging seabed conditions and the extreme metocean conditions in field.

Previous mooring campaigns in the area demonstrated that seabed conditions in the Otway Basin were not favourable for conventional rig anchors. Therefore, Deep Sea Mooring proposed the use of the state-of-the-art 20mT STEVSHARK®REX anchors ballasted with an extra 10mT of material fitted into the fluke as the optimal anchoring solution for the hard cemented soils and boulders.

Motivated by the reduction of risk in mooring line failure, Deep Sea Mooring proposed the use of torque-matched fibre ropes on some lines, to assist in improving the rig wire lifetime. The use of innovative torque-matched fibre rope technology was the first of its kind in Australia.

The anchors were pre-tensioned off the critical path, allowing the rig to commence drilling operations in a timely fashion.

The extreme metocean conditions (and the conservative 25-year return period specified by the Operator) in very shallow water depths of 70m necessitated the requirement for a robust mooring solution. Deep Sea Mooring utilised it’s in house technical and engineering capabilities to propose an 8-point prelaid mooring system.

Deep Sea Mooring proposed the use of a chain-wire system from learnings of a similar type of Rig that operated in the vicinity of the field.

Finally, supported by our extensive mooring technician team in our Karratha yard and the Geelong Supply Base, Deep Sea Mooring was able to provide a large quantity of certified mooring equipment to deliver the highest-quality mooring solution in Australia.

Deep Sea Mooring’s expertise in installation of MODU moorings in Australia, especially in very shallow waters is a testament to the company’s capability to analyse different types of mooring challenges in offshore drilling, provide safe and efficient turnkey mooring solutions. We look forward to continue working in this region and ensuring our clients receive the highest quality of service in demanding and challenging conditions.

FEATURES

Period: December 2020 - present

Main Contractor: Deep Sea Mooring

Products: 20mT STEVSHARK®REX, DSM ADAPS, 84mm R5 Ground Chain, 23mT Surface Buoys and associated Jewelleries

Services: Provision of Engineering Design, Mooring Equipment and Personnel to support offshore operations (inclusive of prelay, hook-up, disconnection and recovery)