Myanmar MD-7 ultra-deepwater project

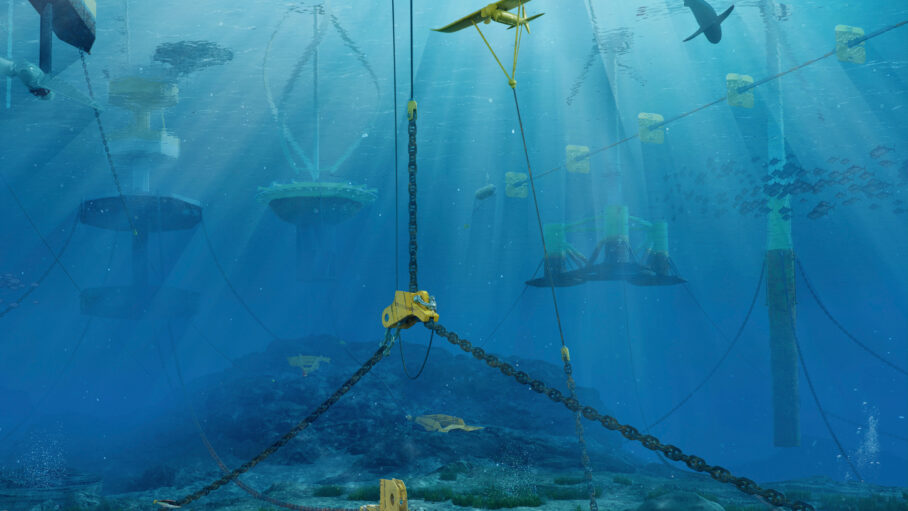

A safe and efficient mooring of a rig in 2,300m of water by deploying a hybrid mooring system consisting of the rig’s self-contained eight conventional wire/chain/drag anchors combined with four insert polyester/chain/drag anchors to improve the station keeping performance.

Thailand’s national petroleum exploration and production company PTTEP and Noble Drilling approached Delmar Systems when it became clear that the mooring contractor they had been working with was in over their head. As the leader in deepwater mooring, Delmar Systems stepped in to provide the requisite expertise.

Delmar Systems worked with the client to refine the deployment and recover procedures to tackle the more time-intensive polyester insert legs off the critical path. Job- and vessel-specific procedures were generated to work around the strengths and weaknesses of the client selected anchor handling vessels.

The Delmar Systems’ mooring plan was crafted to incorporate client-owned mooring equipment to the extent possible. Where additional mooring gear provisions were needed, Delmar Systems mooring equipment inventory available in Singapore was tapped.

Detailed line configuration drawings and lists were generated identifying each component in the system. The dynamic motion mooring analysis from Delmar Systems provided Noble and PTTEP confidence that the designed mooring system was up to the task.

Working together, Delmar Systems engineering and operations teams developed step-by-step deployment and recovery procedures. Mooring engineers numerically simulated the rig move from start to finish to determine the expected loading on the mooring gear, AHTS vessels, and drilling rig winches.

Storyboard drawings were generated and incorporated into the procedures to ensure that all parties were well informed of the plan and related tasks. Detailed pay out and corresponding load schedules were developed for reference during offshore operations.

Mobilizing the anchor handling vessels in Singapore, Delmar Systems outfitted them in a coordinated and strategic manner to facilitate deployment on location. An additional 8,000m of polyester rope, 3,000m of high strength wire rope, anchor handling tools, spares, and consumables deployed for the job.

During the rig move experts from Delmar Systems stayed on board the two AHTS vessels and the rig for coordination, providing direction and oversight to the AHTS vessels to safely and efficiently run and recovering the mooring equipment in the remote ultra-deepwater location.

The vessels demobilized the supplemental mooring equipment in Singapore upon a successful mooring campaign.