Holding power in the most extreme conditions

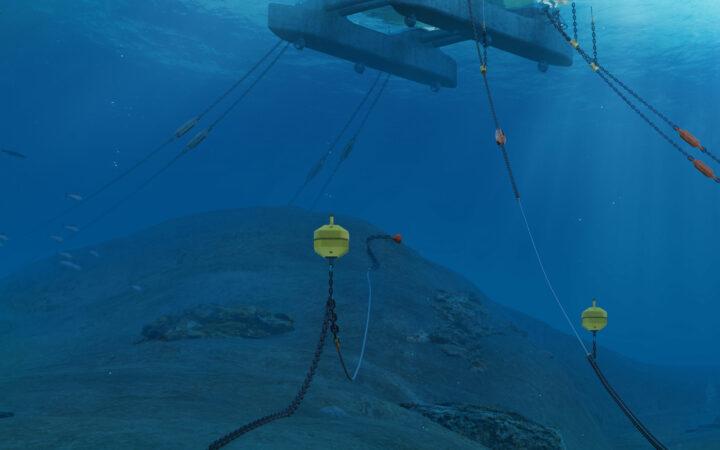

No anchor can deliver the holding power of the STEVSHARK®REX. The application of drag embedment anchors has been expanded to the most remote and challenging territories on earth. Strong soils are no longer prohibitive, opening up the economic possibility for operators to develop new energy resources in a much larger area globally.

The STEVSHARK® anchor design was introduced some 3 decades ago. Since then, the anchor design has proved to be consistently superior over any other drag anchor design available on hard soils and stiff clays. It became the most applied anchor in industries that require high holding power, versatility and stability such as the offshore industry and more recently in the Marine Renewable Energy industry (MRE). A considerable part of drag anchor applications is found under hard soil conditions such as cemented soils, hard clays as well as in areas with soft rock (shallow continental shelf). As even the best drag anchor will not penetrate some of these soils, Vryhof introduced the STEVSHARK®anchor.

In the past the STEVSHARK® was an adapted version of the STEVPRIS® anchor, with a number of reinforcements aimed at a higher structural strength and the ability to penetrate into hard soils. With the STEVSHARK®REX design however, Vryhof chose to take the current STEVSHARK® as a departing point. The set of design parameters was based on the STEVSHARK® inherent strong points, but was to also include improvements that became in reach due to better understanding of anchor design and STEVSHARK®’s behavior over the last decade.

Anchor design

The overall anchor geometry is a combination of improvements in anchor penetration, handling and efficiency. Anchor efficiency of the STEVSHARK® has increased over the current version. Type approval was obtained from main Class Authorities upon finalizing the design for manufacturing. The all-new STEVSHARK®REX was tested several times in traditional and challenging soil conditions consistently behaving as predicted and proving its superior performance.

25 years of hard soil experience

The STEVSHARK® represents 25 years of operational experience with the STEVSHARK® anchor of which some 5,000 were sold. This implies the vast experience recorded in hard soils such as stiff/hard clays, dense sands, cemented and over-consolidated soils and rocks. This experience includes soils where a conventional anchor may penetrate the top layer, but may however prove unable to reach the targetted depth due to complexity of a deeper soil layer. The STEVSHARK®REX tackles these complicated soils more effectively.